Fluid Applied Roofing

What is a Fluid Applied Roofing?

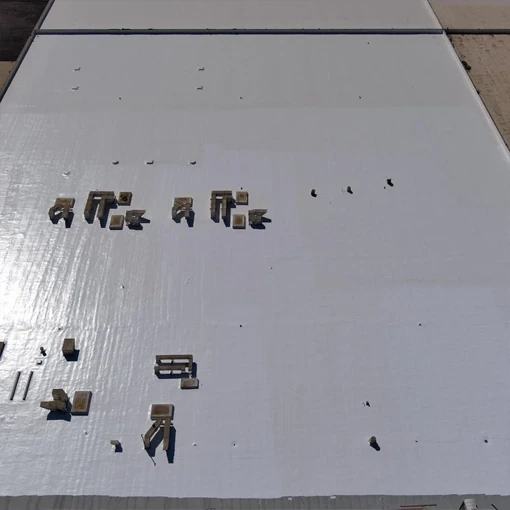

Crownworx Commercial Roof Restoration specializes in fluid applied roofing, an advanced solution for extending the life of commercial roofs without the need for a costly replacement. Over time, commercial roofs suffer from wear and tear due to weather exposure, UV damage, and water infiltration. Crownworx applies a seamless, waterproof silicone coating that protects and revitalizes aging roofs, enhancing their durability and energy efficiency. This coating acts as a protective barrier, preventing leaks, reducing heat absorption, and providing long-term resilience against harsh environmental conditions.

Fluid Applied Roofing is a cost-effective alternative to roof replacement, offering significant benefits in both performance and savings. The process involves thoroughly cleaning the existing roof, repairing any damages, and applying a high-quality silicone membrane that bonds to the surface. This seamless layer eliminates vulnerabilities where leaks often occur, ensuring long-term protection. Additionally, silicone coatings are highly reflective, reducing roof temperatures and lowering energy costs. Crownworx Commercial Roof Restoration helps businesses protect their investments by delivering expert installation and maintenance, ensuring their commercial roofs remain strong, weatherproof, and energy-efficient for years to come.

Benefits of a CROWNWORX Liquid Applied System

Cost - Effective

Opting for a silicone roof coating system can be significantly more budget-friendly than undergoing a complete roof replacement. The difference is removing a functional existing roof system and replacing it with new, can be substantially more than a quality roof restoration using a silicone coating system. Silicone coating systems offer a versatile combination of durability, quality, and waterproofing capabilities compared to alternative roof coating options.

Versatile

Silicone roof coatings are compatible with a wide variety of roofing materials and can be applied to concrete, metal, modified bitumen (MBUR), built-up roofs (BUR), and single-ply roofing systems. Depending on the surface and conditions, a primer is sometimes required.

Quick Application

Silicone roof coatings can be quick and easy to apply. Installing a silicone roof coating doesn’t require any heat-based methods, which can pose safety risks. Having a higher solids content than other coatings, silicone roof coatings require thinner layers to create an effective system.

Water & UV Protection

As compared to other roof coating materials, Silicone roof coatings fare the best against continuous exposure to standing water and rain. The silicone acts as a monolithic layer to prevent water and moisture vapor from penetrating through the system. Silicone coatings protect from damaging UV exposure and can also reflect up to 90% of UV rays from the sun, keeping the building cool and reducing energy costs.

Additional Benefits

Insulation Properties

Seamless roofs provide excellent insulation, reducing heat transfer and lowering energy consumption for heating and cooling.

Reflectivity

Many seamless roofing materials have high solar reflectance, which helps in reducing the heat absorbed by the building, resulting in lower cooling costs.

Long-Term Cost Benefits

While seamless roofing systems may have a higher initial cost compared to traditional roofing materials, their durability and energy-saving properties often lead to long-term cost savings.

Tax Incentives and Rebates

Installing energy-efficient roofing systems, including certain types of membranes, may qualify for tax incentives or rebates, further enhancing cost savings over time.

Recyclability

Many membrane materials are torn off and replaced at the end of their lifespan, seamless systems promote a circular economy and reducing waste sent to landfills.